Bruce Power has reached a major milestone in its Major Component Replacement (MCR), progressing Ontario’s largest clean energy infrastructure project by completing the Unit 3 reactor removal series safely and ahead of schedule.

The removal series was completed faster than in the Unit 6 MCR by leveraging the experience of tradespeople, and innovation through lessons learned and technological advancement. The calandria tube removal, completed July 26, set a CANDU refurbishment record, finishing 11 days ahead of schedule.

“We have seen outstanding performance in completing the Unit 3 MCR removal series, meeting or exceeding our targets for safety, quality and schedule,” said Laurent Seigle, Executive Vice-President, Projects. “Each successive MCR outage brings an opportunity for performance improvement, and we’re committed to returning these units to service safely and successfully to meet Ontario’s clean energy needs well into the future.”

The Unit 3 MCR is the second of six refurbishment projects set to extend the Bruce Power site’s operational life to 2064, supporting the efficient and reliable supply of clean energy for Ontarians to power strong economic growth and electrification needs, as well as cancer-fighting medical isotopes for the world health-care community. Bruce Power’s MCR and Life Extension Program will ensure long-term operation, contributing $10 billion in economic benefit through direct and indirect spending on operational equipment, supplies, materials and labour income.

“This achievement by Bruce Power is yet another example of how Ontario is uniquely positioned to deliver on-time and on-budget nuclear refurbishment at Canada’s largest clean energy infrastructure project,” said Hon. Stephen Lecce, Ontario Minister of Energy and Electrification. “As we plan to generate more clean energy, we celebrate Ontario’s highly skilled workers, advanced technology, and the robust nuclear eco-system that is generating clean, reliable and affordable energy for Ontario families.”

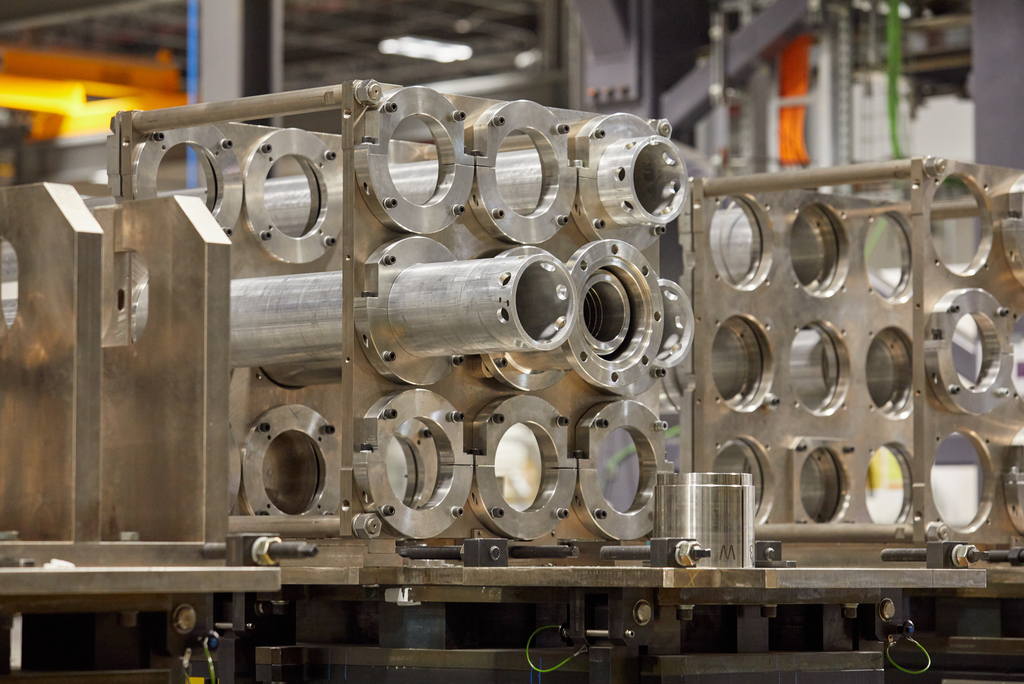

The MCR project team, alongside vendor partners Shoreline Power Group (SPG) (a joint venture between Aecon, AtkinsRéalis and United Engineers & Constructors) and ATS Industrial Automation, spent about nine months removing feeder tubes, pressure tubes, calandria tubes and other important internal components of the Unit 3 reactor in preparation for the installation of new parts that will extend the life of the unit for 40 years. Innovations since the Unit 6 MCR outage helped lead to improved performance.

“Our Tooling Performance Team of highly trained tooling experts and our skilled trades operators are the best at what they do,” said Rob Hoare, Vice-President, MCR Execution. “Many were involved in the tooling development, manufacturing, commissioning during our first run in the Unit 6 MCR. They know how these tools perform and how to make them better and it showed in the complex troubleshooting and results they delivered.”

With the removal series complete, millwrights, boilermakers, and electricians from Shoreline Power Group will transition to commissioning, operating, and maintaining first-of-a-kind, six-axis robotic tooling for reactor inspection and installation work. This includes the replacement of 960 feeder tubes, 480 fuel channels, and 480 calandria tubes. This work will directly and indirectly create and sustain about 1,500 jobs over the next 15 years in Grey, Bruce and Huron counties, and throughout Ontario.

“Building on the success of the ATS automated tooling used in the removal series, the upcoming inspection series will mark the first time an industrial robot will be used on a CANDU reactor refurbishment anywhere in the world,” said Miroslav Kafedzhiev, President of ATS Industrial Automation. “Together with Bruce Power, and in collaboration with skilled and trained tradespeople, we have spent the better part of three years to set a new standard for safety and performance in reactor reconstruction.”

ATS Industrial Automation has played a primary role in designing, testing, and manufacturing the majority of the highly automated tooling systems that will help the skilled trades enhance performance in the vault. The new automated inspection toolset will help tradespeople clean and inspect thousands of components on both faces of the reactor.

Bruce Power is also in the final stages of preparation for the Unit 4 MCR outage, scheduled to begin in 2025, while Units 5, 7 and 8 are also slated for refurbishment over the next 10 years.

“To execute a project of this scale and complexity, it takes an ecosystem of nuclear professionals to work together toward a common goal,” Seigle said. “I’m proud of our entire team and I look forward to continuing to safely deliver these MCR projects.”

To see some of the innovations coming to the MCR project, check out this video on the new automated Inspection and Installation series tooling.

About Bruce Power

Bruce Power is an electricity company based in Bruce County, Saugeen Ojibway Nation Territory, Ontario. We are powered by our people. Our 4,200 employees are the foundation of our accomplishments and are proud of the role they play in safely delivering clean, reliable nuclear power to families and businesses across the province and cancer-fighting medical isotopes around the world. Bruce Power has worked hard to build strong roots in Ontario and is committed to protecting the environment and supporting the communities in which we live. Formed in 2001, Bruce Power is a Canadian-owned partnership of TC Energy, OMERS, the Power Workers’ Union and The Society of United Professionals. Learn more at www.brucepower.com and follow us on Facebook, Twitter, LinkedIn, Instagram and YouTube.