As part of their continuing forged-in-Ontario and made-in-Canada success story, Bruce Power and BWXT Canada Ltd. celebrated the final shipment of feeder tubes for the Unit 3 Major Component Replacement project.

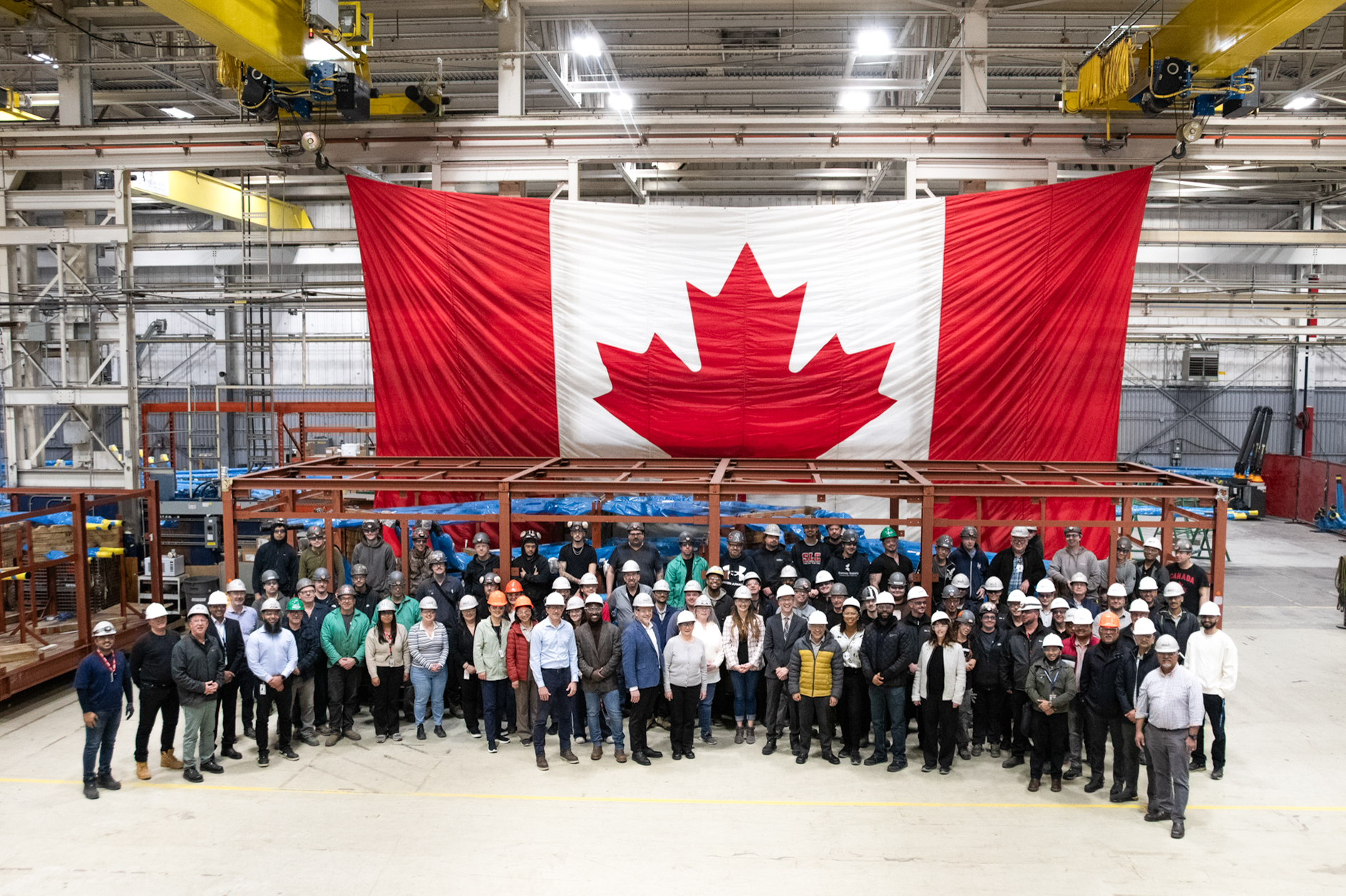

Representatives from both companies were on hand April 17 to see the final shipment leave BWXT’s Cambridge facility, headed for Bruce Power in the Clean Energy Frontier Region of Bruce, Grey and Huron Counties.

Bruce Power’s Canadian at our Core strategy secures good jobs, strengthens the economy and builds on Ontario’s position as a world leader in the production of clean energy and medical isotopes. The contract for BWXT, signed in 2022, is valued at $130 million and involves the fabrication and supply of replacement feeders for Bruce Power’s reactor units 3, 4, 5, 7 and 8.

“This is yet another reminder of how the nuclear industry is helping to secure jobs and driving the economy, while also providing energy security for Canada and providing cancer-fighting medical isotopes for patients around the world,” said David Furr, Bruce Power’s Vice-President, Supply Chain. “Our partnership with BWXT highlights a robust nuclear supply chain that is truly a made-in-Canada success story.”

The Unit 3 MCR outage includes the removal and replacement of major components includes 480 fuel channels, 960 feeder tubes, eight steam generators, and many other upgrades. This will allow Bruce Power to return Unit 3 to service with new reactor components to supply clean energy to the province as demand rises in the decades to come. Shoreline Power Group — a partnership between Aecon, AtkinsRéalis and United Engineers and Constructors — has completed the installation of about 700 of the 960 upper feeders in Unit 3, with the installation of lower feeders to begin this summer.

“Collaboration is so important to ensuring a successful outcome on a project like this, and we appreciate the strong effort demonstrated by the teams at Bruce Power and BWXT to deliver these components on schedule,” said John MacQuarrie, President of Commercial Operations for BWXT. “The skilled workforce at our Cambridge facility produces the quality components that will allow Ontario’s refurbished nuclear fleet to operate safely for decades to come, producing clean, reliable energy.”

Feeder assemblies transport heavy water and are made from seamless carbon steel and involve precise manufacturing processes, including welding, and rigorous testing by BWXT’s engineering team.

The feeders are manufactured by members of United Steelworkers Local 2859 at BWXT’s Cambridge facility, with the project expected to be completed in 2031.

“The United Steelworkers are proud to represent the 500 members of Local 2859 who play a key role in supporting nuclear projects,” said Kevon Stewart, Director of United Steelworkers District 6. “Our highly skilled members are successfully executing this work with the high degree of quality required by the nuclear industry.”

About Bruce Power

Bruce Power is an electricity company based in Bruce County, Saugeen Ojibway Nation Territory, Ontario. We are powered by our people. Our 4,200 employees are the foundation of our accomplishments and are proud of the role they play in safely delivering clean, reliable nuclear power to families and businesses across the province and cancer-fighting medical isotopes around the world. Bruce Power has worked hard to build strong roots in Ontario and is committed to protecting the environment and supporting the communities in which we live. Formed in 2001, Bruce Power is a Canadian-owned partnership of TC Energy, OMERS, the Power Workers’ Union and The Society of United Professionals. Learn more at www.brucepower.com and follow us on Facebook, Twitter, LinkedIn, Instagram, and YouTube.